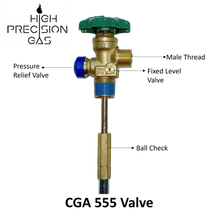

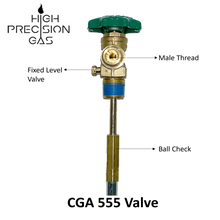

At High Precision Gas, we value our customers and strive to consistently meet and exceed their expectations. With that said, we utilize CGA 555 valves in our LPG cylinders for liquid-to-liquid service to ensure Compressed Gas Association (CGA) and National Fire Protection Association (NFPA) compliance, safety, and ease of use. Equipped with excess flow valves and liquid withdraw tubes, they are designed for liquid withdrawal of DOT cylinders. They are most often used with heavy BTU loads found in industrial uses.

CGA 555 Valve Features include:

- O-ring stem seal design

- Nylon tapered seat disc for positive closure

- Self-tapping screw secures handwheel to stem and reduces the possibility of handwheel vibrating loose while in transit

- Excess flow (ball) check valve limits flow in case of line breaks or accidental disconnects

- Fixed level vent valve

- Full-length liquid withdrawal tube

- Pressure relief valve

- Furnished with 1/2" O.D. brass withdrawal tube with "T" dimension of 44"

Materials:

- Body: Forged Brass

- Handwheel: Aluminum Die Cast

- Seat Disc: Nylon

- O-Rings: Reslient Rubber

- Relief Spring: Stainless Steel

- Stem: Brass

Why CGA 555 (and not CGA 510) when used in liquid-to-liquid butane/propane service?

- CGA specifies to use the CGA 555 in a liquid application.

- NFPA 58 Liquified Petroleum Gas Code requires CGA 555 outlet and internal excess-flow valve for use in liquid service for capacity less than or equal to 420 lb. propane capacity.

- The CGA 510 is the same fitting used in other gas applications (e.g., barbeque grills, gas stoves, outdoor gas heater), and therefore a CGA 510 with a liquid withdrawal tube attached can be easily mistaken and connected to a vapor gas application. This can lead to a very dangerous scenario.

- Well known valve OEMs (i.e., Rotarex, Rego, Sherwood, Marshall Excelsior) do not (and will not) sell a CGA 510 with a liquid withdrawal tube. Any CGA 510 with a liquid withdrawal tube is modified without the express consent of the valve OEM, and most have been discovered to not have an internal excess-flow provision installed.